Powder Cores

Supplier of Powder Cores for Inductors and Flyback Transformers

Magnetics® is a manufacturer of high quality powder core materials including Kool Mu® (sendust), MPP (molypermalloy), Kool Mµ® MAX, Kool Mu® Hƒ, Edge® , High Flux, XFlux®, and 75-Series. Magnetics powder cores are distributed air gap cores primarily used in power inductor applications such as switched-mode power supply (SMPS) output filters, also known as DC inductors. Other power applications include differential inductors, boost inductors, buck inductors, and flyback transformers. Notable characteristics of Magnetics’ powder core materials are high resistivity, low hysteresis and eddy current losses and excellent inductance stability under both DC and AC conditions. In addition, Magnetics powder core materials are not pressed with an organic binder, so there is no thermal aging.

While all ten materials are used in power applications, each has its own advantage:

- MPP material has many outstanding characteristics including low core losses, highest Q, and highest temperature stability compared with other materials.

- For small core size in a DC bias dominated design, High Flux material should be considered.

- For the most efficient design using the smallest core, Edge is the best choice, offering the highest DC bias and approximately 40% lower losses compared to High Flux.

- XFlux can be a lower cost alternative to High Flux, in situations where the higher core losses and more limited permeability availability of XFlux is acceptable.

- XFlux Ultra cores offer the same high saturation found in standard silicon-iron XFlux while providing a 20% improvement in core loss.

- Kool Mµ (commonly referred to as sendust) is well known for the moderate cost and has significantly lower losses and substantially better thermal properties when compared to powdered iron cores.

- The combination of high DC bias and low core loss density makes Kool Mµ MAX the optimal solution for high efficiency, high power inductors.

- Kool Mµ Hƒ powder cores, optimized for frequencies 200-500 kHz, are a cost-effective solution for minimizing power losses in high frequency power supplies.

- Magnetics' lowest loss powder core material, Kool Mμ Ultra has DC bias superior to Kool Mμ and comparable to Kool Mμ Hƒ, with core losses almost 30% below Kool Mμ Hƒ.

- The relatively high saturation flux density of 75-Series cores makes them a low-cost solution in applications where stable inductance under load is necessary.

Powder Core Shapes

Powder cores are available in a variety of geometries including toroids, E shape, U shape, blocks, round blocks, cylinders, and EQ, LP, and EER shapes. The material properties of powder cores and the flexibility of these geometries make them ideal for a multiple applications and custom assemblies.

Learn More

Large Toroid Sizes

Five large sizes have been added to the toroid powder core line, including the massive 165 millimeter core. Large Powder Core toroids are a cost-effective option for high current applications, such as: UPS, large Power Factor Correction (PFC) chokes and inverters for renewable energy.

Learn More

Property Curves

View Powder Core Material Property Curves including Normal Magnetization curves, Core Loss Density curves, Permeability versus Temperature curves, Permeability versus DC Bias curves, Permeability versus AC Flux, and Permeability versus Frequency curves.

View Property Curves

Designing at High Temperatures

Thermal considerations are a basic part of power electronics design. Having this understanding is vital for selecting the best type of material for each application, and for ensuring that the magnetic device will function safely at its maximum operating temperature.

View Design Guide

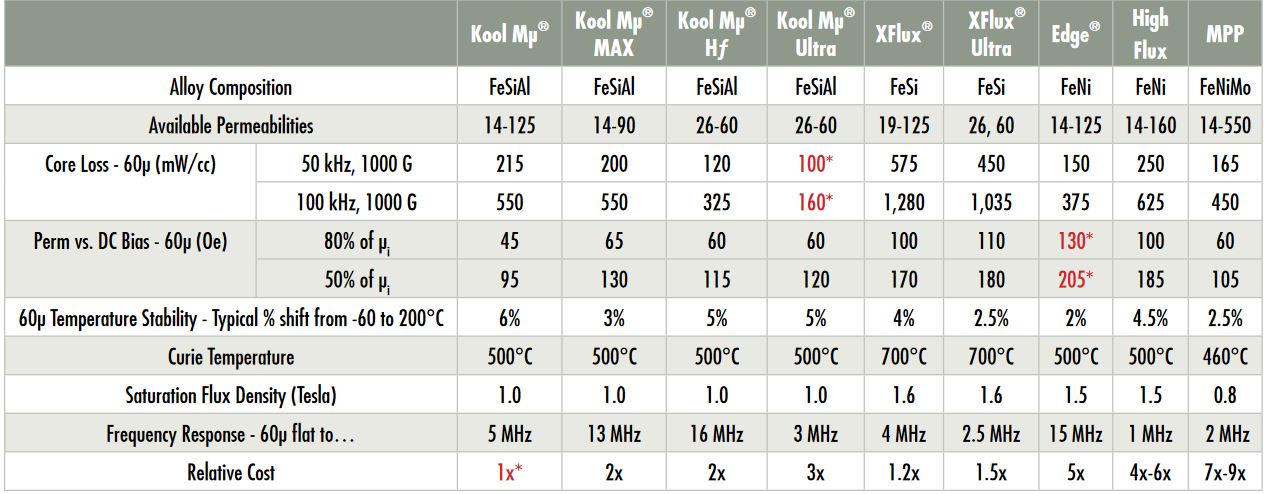

Powder Core Materials Comparison

Click on table to zoom