Tape Wound Cores

Supplier of Tape Wound Cores for Converters, Inverters, and MagAmps

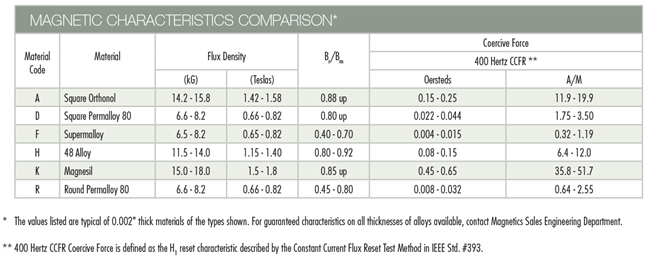

Magnetics® is a manufacturer of Tape Wound cores, which are key components of complicated electronic circuitry found in high reliability applications including military, aerospace, communications, down hole drilling, and nuclear reactors. Tape Wound cores and Bobbin cores are made from thin strips of high permeability nickel-iron alloys such as Square Orthonol®, Square Permalloy 80, Round Permalloy, Supermalloy, and 48 Alloy, or grain oriented silicon iron known as Magnesil®. Nanocrystalline and Amorphous cut cores are also available. Request a quotation for Magnetics Tape Wound cores!

Nanocrystalline

In order to create a nanocrystalline core, amorphous metal must be annealed, which results in an extremely fine and uniform nanocrystalline microstructure. These cores are commonly used in the applications of current transformers and common mode chokes, as they demonstrate high permeability, high saturation, and low power loss.

Additionally, common mode chokes that are produced with nanocrystalline material can be used in a multitude of applications and industries, including switched-mode power supplies (SMPS), uninterruptible power supplies (UPS), solar inverters, frequency converters, EMC filters, and multiple automotive and welding applications. Compared to ferrite cores, nanocrystalline cores offer high saturation induction, higher permeability levels, and a wider operational range of temperature.

Amorphous

Created from metallic glass materials with an amorphous atomic structure, amorphous cut cores offer higher resistivity than nanocrystalline cores, as well as excellent efficiency and frequency response. Amorphous cores allow for smaller and lighter designs in many high frequency, low loss applications, including uninterruptible power supplies (UPS), SMPS power factor correction (PFC) chokes, inverters, filter inductors, and high frequency power transformers and inductors.

Compared to ferrite cores, amorphous cores offer a wider operational range of temperature as well as significantly higher flux capacity and impedance at high frequencies. They also offer high permeability compared with conventional silicon steel. Amorphous cut cores are strong in compression and tension, resisting fracture and corrosion.

Supermalloy

Supermalloy is a specially processed 80% nickel-iron alloy, designed specifically to reach the pinnacle of high initial permeability and low coercivity. For reference, initial permeability ranges between 40,000 and 100,000, while the coercive force is about one-third that of Square Permalloy 80. Supermalloy is most commonly used in applications where low loss is mandatory, including ultra-sensitive transformers (such as pulse transformers) and magnetic amplifiers.

Square Permalloy 80

Manufactured to meet the high squareness and core gain requirements of magnetic preamplifiers and modulators, Square Permalloy 80 is a non-oriented alloy made from 80% nickel-iron. Because of its capability to provide maximum magnetic permeabilities and minimal core losses at low field strengths (a common industry requirement), Square Permalloy 80 is commonly used in a number of converters and inverters. Compared to Orthonol, Square Permalloy 80’s core gain is about 1.7 times higher.

Square Orthonol

Square Orthonol is manufactured to meet specific circuit requirements for very high squareness, induction, and core gain. A grain-oriented alloy made from 50% nickel-iron, Square Orthonol is often used in saturable reactors, high gain magnetic amplifiers, bistable switching devices, and power inverter-converter applications, while time delays, flux counters, and transductors also require the alloy for its extremely square hysteresis loop.

48 Alloy

Another 50% nickel-iron alloy known as 48 Alloy offers lower squareness and coercive force than Square Orthonol. This makes 48 alloy very useful in devices that need lower coercive force, including special transformers, saturable reactors, and proportioning magnetic amplifiers. It is worth noting that AC core losses are also typically lower than that of Square Orthonol alloys.

Magnesil

Typically used in high quality toroidal power transformers, current transformers, and high power saturable reactors as well as magnetic amplifiers, Magnesil is a grain-oriented 3% silicon-iron alloy known for its high squareness and moderate core loss. Due to its high Curie temperature, it is also commonly used in magnetic devices that are exposed to extreme temperatures up to and exceeding 500ºC (932ºF). (Due to the case temperature limitations, only uncased cores should be used above 200ºC.)

Round Permalloy 80

Specifically processed to create high initial permeability and low coercive force, Round Permalloy 80 is a non-oriented 80% nickel-iron alloy with lower squareness and AC loss than square alloys. Round Permalloy 80 is most useful in applications where signals are very low and DC currents are non-existent, such as interstage transformers, as well as areas requiring high accuracy and minimal loss, such as current transformers.

Tape Wound Core Part Number Identification

How to Order: Magnetics Tape Wound Cores