Learn More about Ferrite Shapes

For more information on Ferrite Shapes, visit the Technical Documents library for the Ferrite Core Catalog. Other reference materials including technical bulletins, application notes and white papers are also available for download.

E, I Cores

E cores are less expensive than pot cores, and have the advantage of simple bobbin winding plus easy assembly. E cores do not, however, offer self-shielding. Lamination size E cores are available to fit commercially offered bobbins previously designed to fit the strip stampings of standard lamination sizes. Metric and DIN sizes are also available. E cores can be pressed to different thicknesses, providing a selection of cross-sectional areas. Typical applications for E cores include differential, power and telecom inductors, as well as broadband, power, converter and inverter transformers.

Industry standard E core sizes include: E65, E80, E100

Hardware: E core bobbins for different cross sections are available. E cores can be mounted in different directions and, if desired, provide a low profile. Printed circuit E core bobbins are available for low profile mounting.

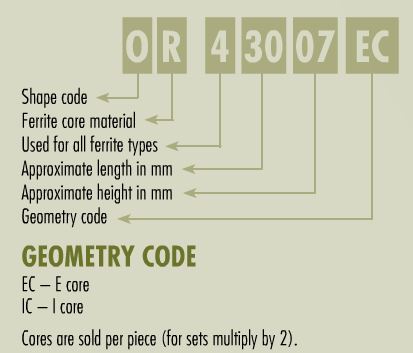

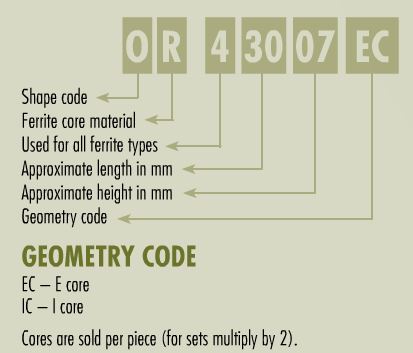

How to Order E, I Cores

EFD Cores

The industry standard economical flat design of EFD cores offers excellent space utilization for transformers or inductors. The optimized cross-sectional area is ideal for very flat compact transformer applications. EFD cores are ideal for compact transformers and inductor applications.

Industry standard EFD core sizes include: EFD10, EFD12, EFD15, EFD20, EFD25, EFD30

Hardware: EFD core accessories are available.

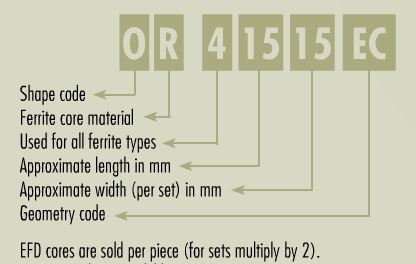

How to Order EFD Cores

ETD Cores

ETD cores are an economical choice for transformers or inductors. ETDs offer a round centerpost for minimum winding resistance. Also, dimensions are optimized for power transformer efficiency. Typical applications of ETD cores include differential inductors and power transformers.

Industry standard ETD core sizes include: ETD29, ETD34, ETD39, ETD44, ETD49,ETD54, ETD59

Hardware: ETD core accessories are available.

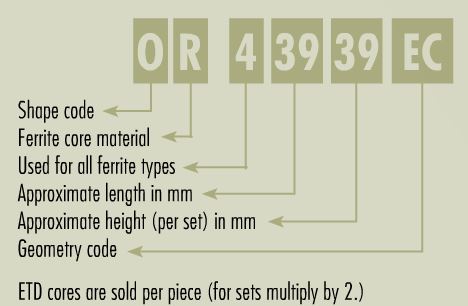

How to Order ETD Cores

EER Cores

EER cores (sometimes referred to as ER cores) are an economical choice for transformers and inductors. The round centerpost offers the advantage of a shorter winding path length than the winding around a square centerpost of equal area. Differential inductors and power transformers are typical applications of Magnetics EER cores.

Industry standard EER core sizes include: EER28/14, EER28/17, EER35, EER40, EER42,EER48, EER54

Hardware: EER core accessories are available.

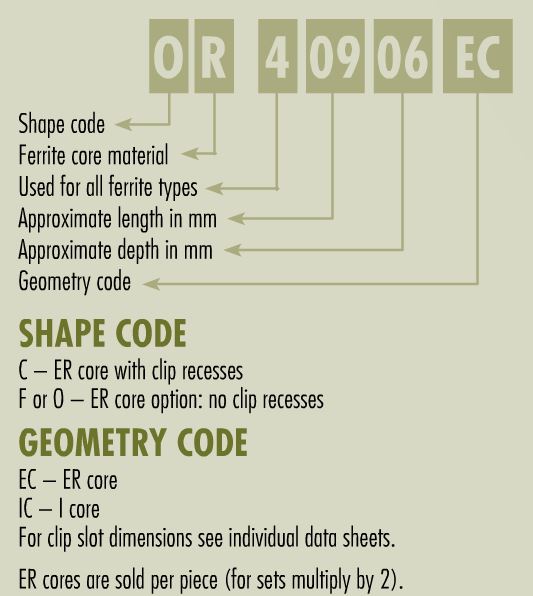

How to Order EER Cores

EC Cores

A cross between a pot core and an E core, EC cores have a round center post that provides a wide opening on each side, and therefore minimum winding resistance. The long legs support low leakage inductance designs. EC cores are typically used in differential inductor and power transformer applications.

Industry standard sizes include: EC35, EC41, EC52, EC70

Hardware: EC cores have standard channels for clamping assemblies. Plain EC bobbins, EC printed circuit bobbins and EC clamps are available for most sizes.

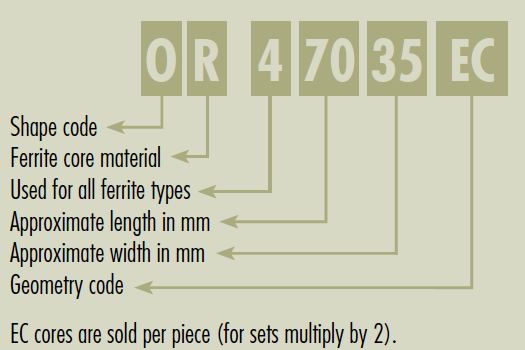

How to Order EC Cores

U, I, UR Cores

U shape cores are ideal for higher power operation in tight spaces or unusual form factors. The long legs of a U core support low leakage inductance designs and facilitate superior voltage isolation. U/I combinations facilitate economical assembly. U cores are ideal for power transformer applications.

Industry standard U and UR core sizes include: U26, U93, U100, U126, UR42, UR59

Corresponding I cores are available for most sizes.

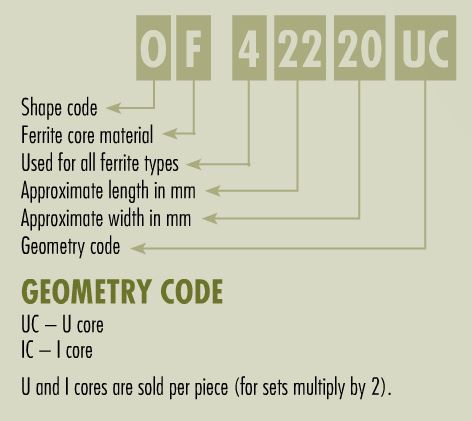

How to Order U, I, UR Cores

Planar E, I Cores

Planar E cores are offered in all of the IEC standard sizes, as well as a number of other sizes. The leg length and window height (B and D dimensions) are adjustable for specific applications without new tooling. This permits the designer to adjust the final core specification to exactly accommodate the planar conductor stack height, with no wasted space. I-cores are also offered standard, permitting further flexibility in design. E-I planar combinations are useful to allow practical face bonding in high volume assembly, and for making gapped inductor cores where fringing losses must be carefully considered due to the planar construction. Differential inductors and DC/DC, AC/DC converter are typical applications for planar cores.

Industry standard planar E core sizes include: E18, E22, E32, E38, E43, E58, E64, E102

Corresponding I cores are available for most sizes.

Hardware: Planar core clips are available in many cases.

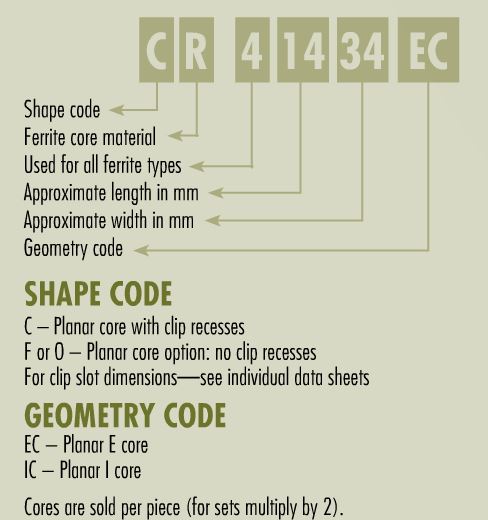

How to Order Planar E, I Cores

ER Cores

ER cores ( also known as EQ cores) are a cross between E cores and pot cores. The round centerpost of the ER core offers minimal winding resistance. In addition, they offer better space utilization and shielding than with rectangular center leg planar cores. When compared with non-planar cores, ERs offer minimal height and better thermal performance. Typical applications of ER cores include differential inductors and power transformers.

Industry standard ER core sizes include: ER13, ER20, ER25, ER30

Corresponding I cores are available for most sizes.

Hardware: E/I combinations facilitate economical assembly. E/I surface mount accessories are available.

How to Order ER Cores